Where does the time go? If you have a toddler it goes on entertaining them, trying to catch up on sleep or, if like me, they are spending their first winter season in nursery, permanently unwell. That’s my excuse and I’m sticking to it.

Nonetheless it should be pretty clear from that intro that it’s been a slow few months. I can’t blame it all on the little one, a combination of boring jobs (read painting, or worse prepping!) and overthinking the planning mean that not a lot has been getting done. I am here now though so let me catch you up.

The next few months are spent tackling a couple of things people who have built Exocets say:

- When fitting the floor make sure you don’t rivet where the seats are going to mount

- It’s a lot easier to fit the tunnel and firewall before you fit the floor

So before starting on the floor I decided to check where exactly the seats would be mounting, so started somewhat unusually with the seat rails. As in the build guide I trimmed the edge, bent the ends flat and offered them up to the car. Then I hit my first “it’s a kit car” moment, the holes on the rails didn’t line up. I spent a little time thinking about it, popped a message on the Facebook group but nothing really came of it so I decided that a) I’d roughly be able to guess where the holes would be needed and b) anything more I can worry about later. So back into the corner of the garage went the seat rails.

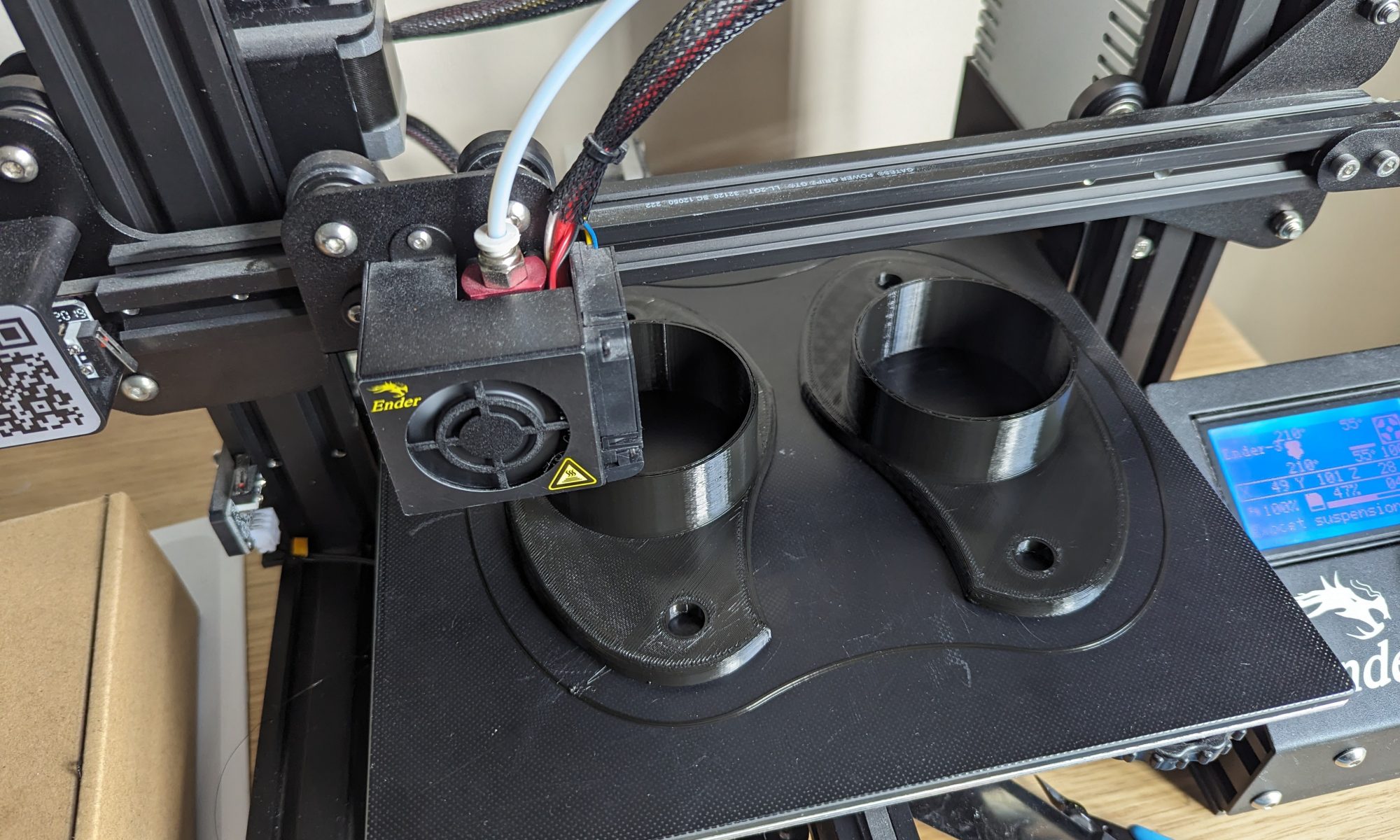

On to the floor, pun intended. I started by clamping the floor to the frame and seeing what was what. I noticed that the cut wasn’t perfect all the way around, nothing major but where there was a little excess material I decided to cut this away. Then with the floor clamped in place and a small template made on the 3d printer to mark a hole every 100mm I set about punching then drilling holes for the rivets.

Lesson for future builders – as you drill holes, drop a rivet in to keep the floor stable, it is entirely possible for the floor to move slightly part way around drilling regardless of how many clamps you use.

Despite that slight hiccup the holes were all drilled in the aluminium and the frame, I used a touch up paint of the blue RAL colour to paint the holes for a slight extra bit of rust protection. Probably pointless but easy too.

I decided it was worth treating/painting/wrapping the floor before fitting. I used Upol Raptor truck bed liner as the covering for the top of the floor, and just some Hammerite Stone Chip paint on the bottom. On the top I wanted to keep clean metal where I would be using adhesive to ensure a good solid connection to the frame so I laid the floor on the frame, marked out where the edges were and cut out the covering that came on the aluminium to easily mask of that area. I’m happy to say it was quite successful. The bed liner paint is a two part mix so I used around a third of each amount, poured it onto the metal and brushed it around with a small paint roller. The thick coat and the paint roller gave a slightly textured finish that I like and should help in the cockpit.

By the way, if anyone knows where I can get the words “I f**ked up, please turn over” made up in a large vinyl sticker do let me know.

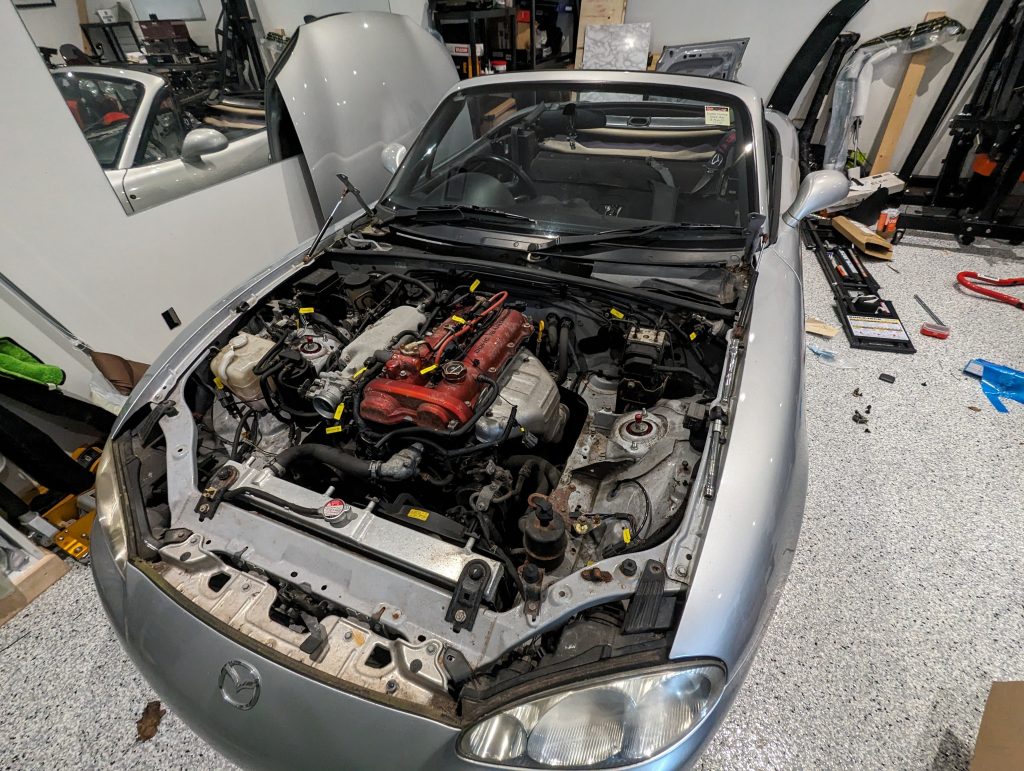

While all of this was going on I was tinkering with other things, I made up another cover for the engine on the 3d printer, this time for the oil filter/coolant sandwich plate thread. Ultimately I will get round to giving the block a quick coat of enamel just to tidy it. I also organised some bolts that I might be able to reuse – lots of M6x16 on a MX5 apparently.

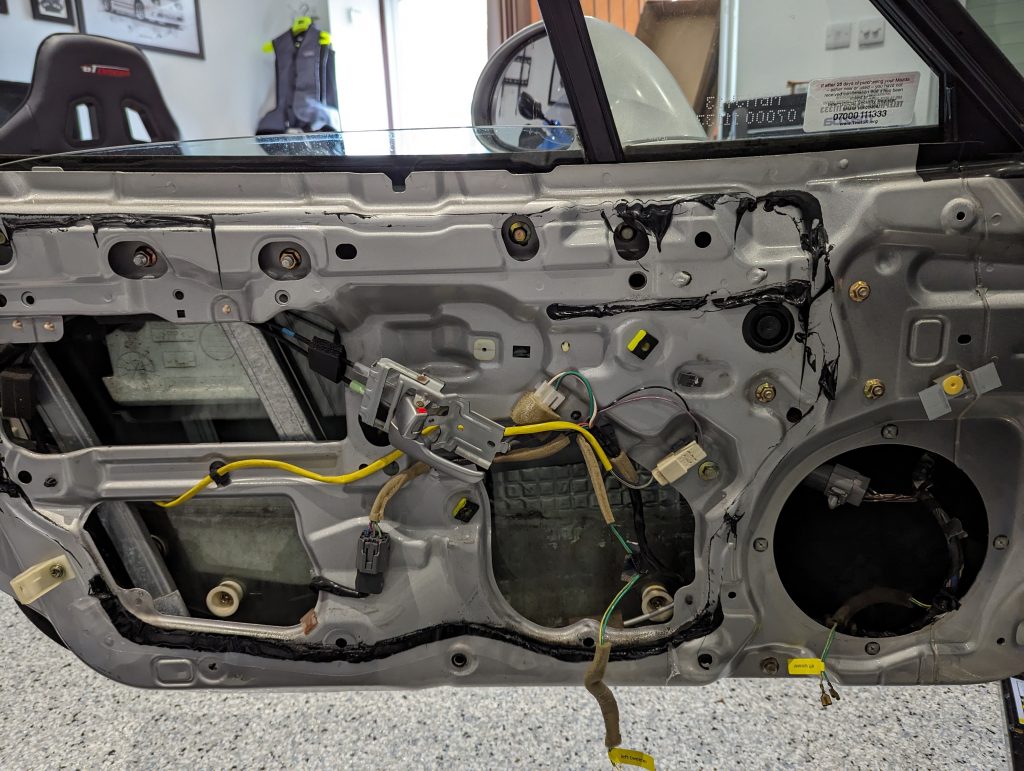

By far my nemesis over this time (apart from the cold weather preventing any painting getting done) was the diff bushes. I can’t adequately describe my process or indeed my feelings about the process without using a significant number of expletives. Suffice to say it took over 3 months, a new lump hammer, a new set of chisels, a new blowtorch, more bashed thumbs than I have fingers, skinned knuckles, burning rubber fumes and a couple of chips in the housing that will need polishing out in order to get those metal and rubber pieces of *********** out of the case. The first photo here is from the 9th November, the first bushing parted ways with the diff case on the 15th March.

One last thing then since I did mention it at the start, I spent a good amount of time deciding whether or not to fit the floor. On the one hand if I leave the floor off it will (or so people on the forum would have me believe) make fitting the tunnel and firewall easier. On the other, fitting the floor means once that’s done I can turn the frame over and fit to the skate (when it’s ready) only once, not having to turn it back again to fit the floor. I’ll save the answer for the next post but it’s a good example of me getting stuck on a decision so long that it was more counter-productive than either of the negative outcomes would have been anyway. One day I’ll learn just to pick one.

And I think that’s about caught up for now.